Buying used laboratory equipment can be a smart way to stretch a budget without sacrificing capability. But used does not mean risk-free. Most expensive problems come from a few predictable mistakes—usually made before the purchase order is even issued.

Here are the most common mistakes companies make when purchasing used lab equipment, and practical steps to avoid them.

1) Buying Based on Price Alone

A low price is attractive, but the cheapest unit often becomes the most expensive after missing parts, failed startup, or costly service calls.

Avoid it: Compare total cost of ownership:

- Condition and testing status

- Included accessories (rotors, probes, cables, modules)

- Return policy and warranty terms

- Shipping method (crate vs. loose freight)

2) Not Confirming What “Tested” Actually Means

Sellers may use “tested” to mean anything from “powered on” to “fully verified in operation.” Those are not the same.

Avoid it: Ask for specific test details, such as:

- Power-on and self-test results

- Functional checks (speed, temperature stability, optics, pressure, etc.)

- Error logs or diagnostic screenshots (when available)

- A short video showing operation (often the fastest proof)

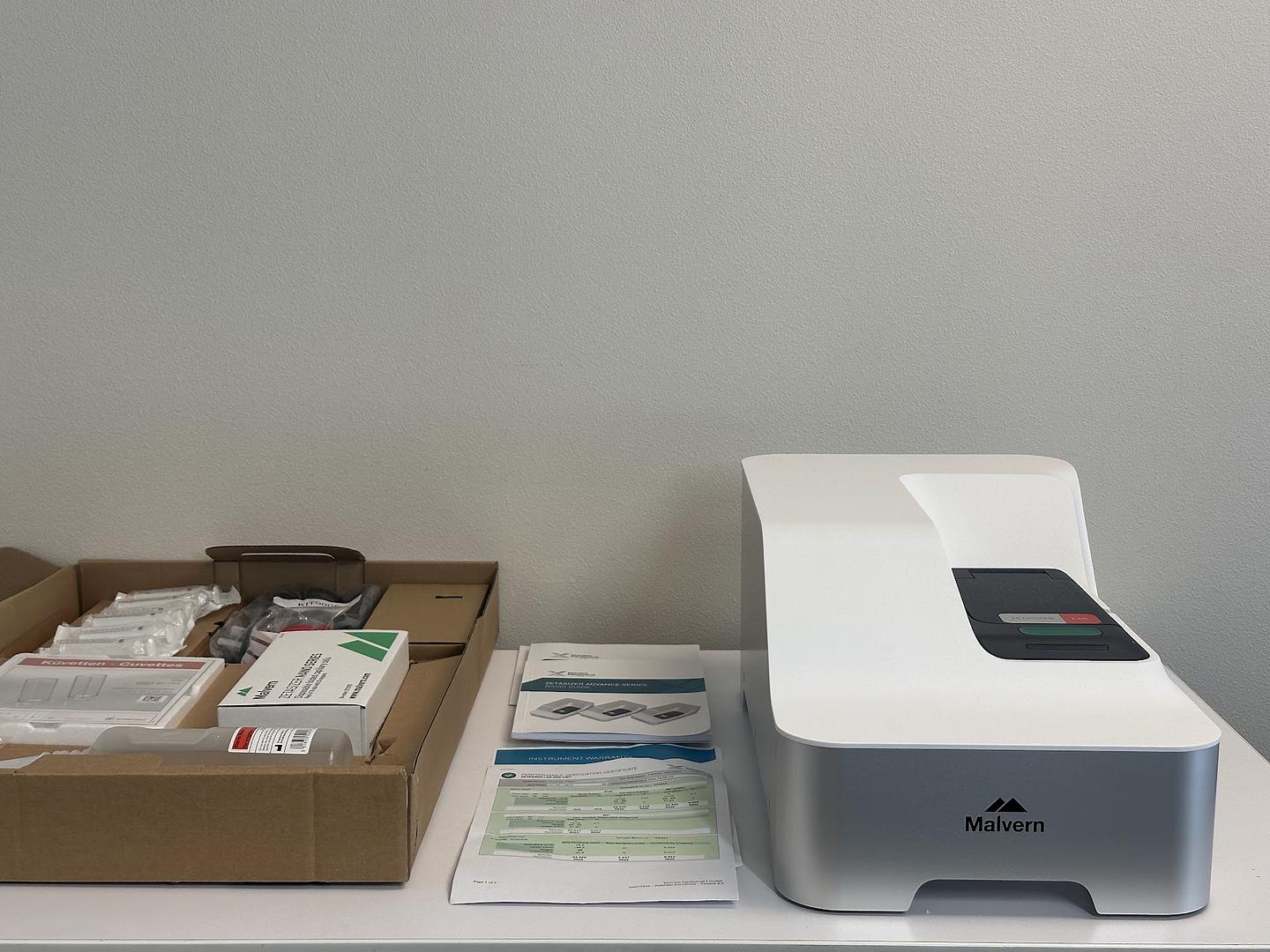

3) Ignoring Missing Accessories and Consumables

Used equipment frequently requires accessories to be usable. A centrifuge without a rotor, a microplate reader without a power supply, or a balance without the correct pan/adapter can delay your workflow.

Avoid it: Request an “included items list” and confirm:

- Exact accessories and part numbers (if possible)

- Firmware/software licensing status (where relevant)

- Any required adapters, lids, carriers, or special cables

4) Skipping Serial Number Verification

The serial number helps confirm the exact configuration, year range, and sometimes service history. If the seller cannot provide it, that’s a risk signal.

Avoid it: Always ask for:

- A clear photo of the serial plate

- Model variant details (not just the generic series name)

5) Not Asking About Calibration, Maintenance, or Service Readiness

Some instruments can be “working” but still not ready for regulated or high-accuracy applications without calibration or preventive maintenance.

Avoid it: Clarify expectations:

- Is calibration included, optional, or not available?

- Are maintenance items due soon (seals, bearings, lamps, pumps)?

- Can the seller recommend basic commissioning steps upon arrival?

This is especially important for analytical equipment, balances, spectrophotometers, and temperature-controlled systems.

6) Underestimating Shipping Risk

Lab equipment is not like shipping office supplies. The wrong packing method can turn a good unit into a damaged one—especially for heavy instruments or delicate optics.

Avoid it: Confirm packing and freight details:

- Will it ship in a custom crate, on a pallet, or loose freight?

- Are fragile components secured and cushioned properly?

- Is insurance included, and what is the claim process?

A professional seller should be comfortable explaining how they pack and why.

7) Assuming Returns Are Simple

Returns on large or sensitive equipment can involve freight costs, restocking conditions, and timelines.

Avoid it: Before paying, confirm in writing:

- Return window (e.g., 14 days)

- Who pays return freight if the unit is defective vs. “changed mind”

- What qualifies as a functional failure

- Whether returns require original packaging/crate

8) Not Matching the Equipment to the Actual Use Case

Teams sometimes buy a “great deal,” then realize it does not fit the workflow: wrong voltage, wrong throughput, missing features, or incompatible consumables.

Avoid it: Create a simple checklist before purchase:

- Power requirements (110/120V vs 220/240V)

- Bench space and weight limits

- Throughput and capacity needs

- Compatibility with existing lab processes and standards

A Simple “Smart Buyer” Checklist (Copy/Paste)

Before purchasing used lab equipment, confirm:

- Serial number photo and exact model variant

- What functional testing was performed

- Included accessories and missing items

- Packing method (crate/pallet) and insurance

- Return policy and warranty terms

- Calibration/service readiness expectations

Conclusion

Used laboratory equipment can deliver excellent value when you buy it correctly. The goal is not just finding a working unit—it is reducing risk through verification, documentation, and proper shipping.

If you want consistent outcomes, buy from sellers who can show testing details, provide complete included-items lists, and pack equipment for safe transit.