Choosing between used and refurbished laboratory equipment can save a lab thousands of dollars, but only if you understand the difference. In 2025, more research facilities, universities, hospitals, and biotech startups are buying pre-owned instruments to reduce costs without sacrificing performance. However, the terms “used” and “refurbished” are often confused, even though they represent two very different levels of quality. This guide explains what each option means and how to decide which is the best choice for your laboratory.

What Does “Used” Lab Equipment Mean?

Used lab equipment is typically sold in its existing condition, with no repairs or part replacements performed. The seller may power it on, but often does not test it under real working conditions. The equipment comes exactly as it was when removed from the previous lab.

Typical characteristics of used equipment include:

• Sold as-is

• May have cosmetic wear or missing accessories

• Testing may be limited

• No refurbishment work performed

• Little or no warranty

Used equipment is the lowest-cost option, suitable for labs with limited budgets or in-house technicians who can handle repairs if needed.

What Does “Refurbished” Lab Equipment Mean?

Refurbished laboratory equipment goes through a professional restoration process to restore performance. This usually includes full testing, repairing or replacing worn components, deep cleaning, calibration when applicable, and verification that the instrument functions as intended.

Typical characteristics of refurbished equipment include:

• Fully tested under working conditions

• Replaced or repaired components

• Cleaned and inspected

• Often calibrated

• Usually includes a warranty

• Often includes required accessories

Refurbished equipment offers significantly more reliability while still costing far less than buying new.

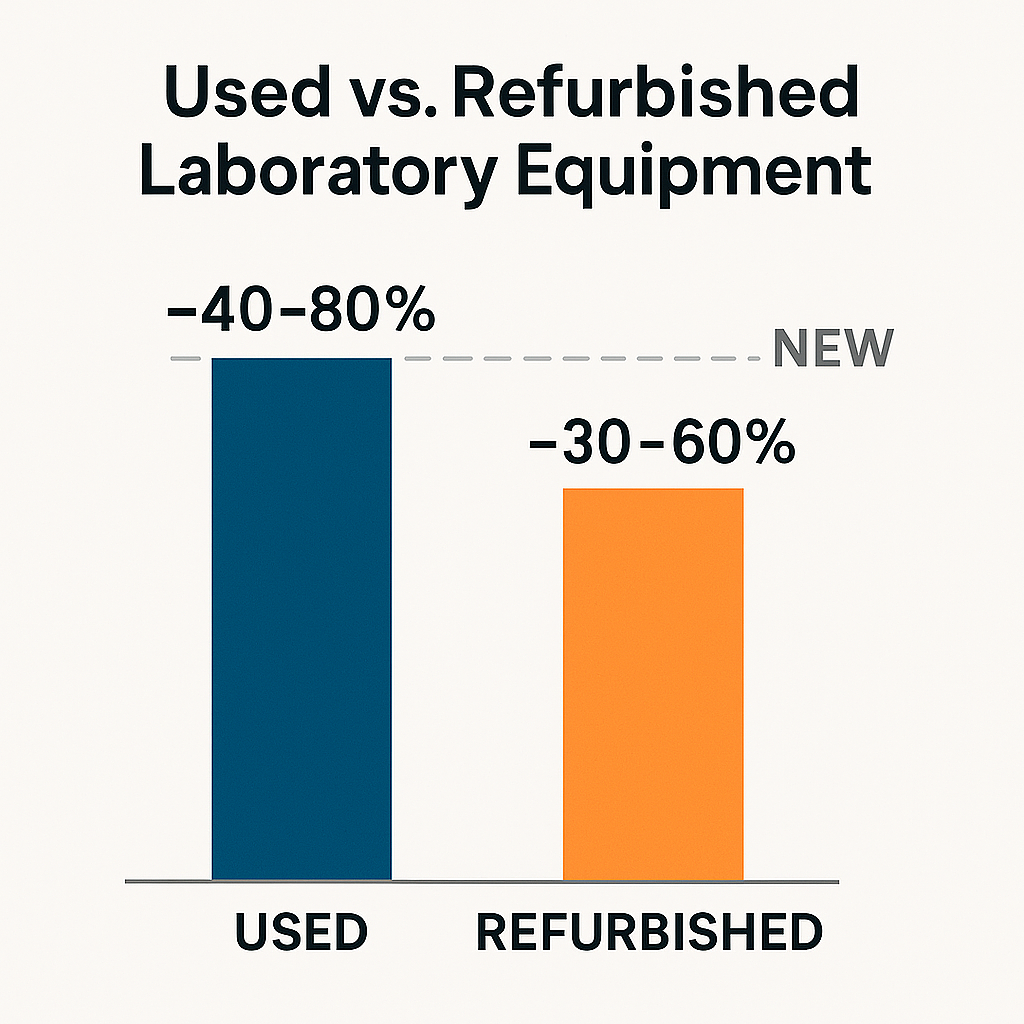

Price Comparison: Used vs. Refurbished in 2025

Although prices vary by brand and condition, these trends are consistent:

• Used equipment is usually 40–80% cheaper than new

• Refurbished equipment is usually 30–60% cheaper than new

• Refurbishment increases reliability but still provides major savings

For high-value instruments such as centrifuges, chillers, PCR machines, microscopes, and HPLC systems, refurbished equipment often offers the best balance of cost and performance.

Performance Differences You Should Expect

The largest difference between used and refurbished equipment is reliability. Used equipment may work perfectly or may fail shortly after installation, depending on its previous environment and condition. Refurbished equipment is tested and verified to meet performance expectations before shipping.

Used equipment may have:

• Hidden internal issues

• Worn mechanical parts

• Calibration problems

• No guarantee of performance

Refurbished equipment typically offers:

• Consistent operation

• Longer lifespan

• Ready-to-use condition upon arrival

For labs that rely on accuracy or uptime, refurbished equipment provides greater peace of mind.

Risks to Consider

Risks of used equipment include hidden defects, missing parts, lack of testing, and no warranty. Risks with refurbished equipment are usually related to the quality of the refurbishing process, since not all sellers follow the same standards.

This makes choosing a trustworthy reseller more important than choosing between used or refurbished alone.

How to Choose the Best Option for Your Lab

Choose used equipment if your lab has a tight budget, has access to in-house repair technicians, or needs simple instruments with low cost and low risk.

Choose refurbished equipment if you need reliability, accurate performance, warranty protection, or if the instrument is high-value or critical to your workflow. For complex or sensitive devices—centrifuges, chillers, microscopes, HPLC systems, and PCR machines—refurbished is usually the better long-term choice.

Need Help Choosing the Right Equipment?

Labtain specializes in supplying, testing, packing, and shipping both used and refurbished laboratory equipment. We provide clear information, verified testing, and professional packaging so your equipment arrives safely and ready for use. If you need recommendations or want help comparing models, conditions, or prices, contact us for guidance or a quote.